Last Updated on May 11, 2024 by Sharaj

Are you serious about your woodworking or DIY projects? Then, you need a table saw in your workshop arsenal. Named on the table that you get with it, the table saw is one of the best machines for quick and precise cuts.

Whether you are looking to purchase a new table saw or you already have one; in both the situations you need to know its usage. Once you have some basic ideas about how to use a table saw, you can make accurate cuts without compromising on your safety.

Table Saw Basics

A table saw is a versatile tool that gives you the platform to cut woods longitudinally (rip cuts), cross-cut, mitre cut (cross-cuts at an angle) and bevel (cut edges that are not 90 degrees).

So, a table saw is helpful when you need to make cabinets, frame, furniture pieces or any other wooden structures. However, to make the most out of it, you need to know the basics.

Standard table saw are available between £150 to £700. For professional quality versions, you might have to spend up to £2000. Table saws are available according to the size of the blades they can accommodate. 10-inch table saws are the most common, but you will also find 8-inch version useful for small projects and 12-inch version that you can use to cut thick materials.

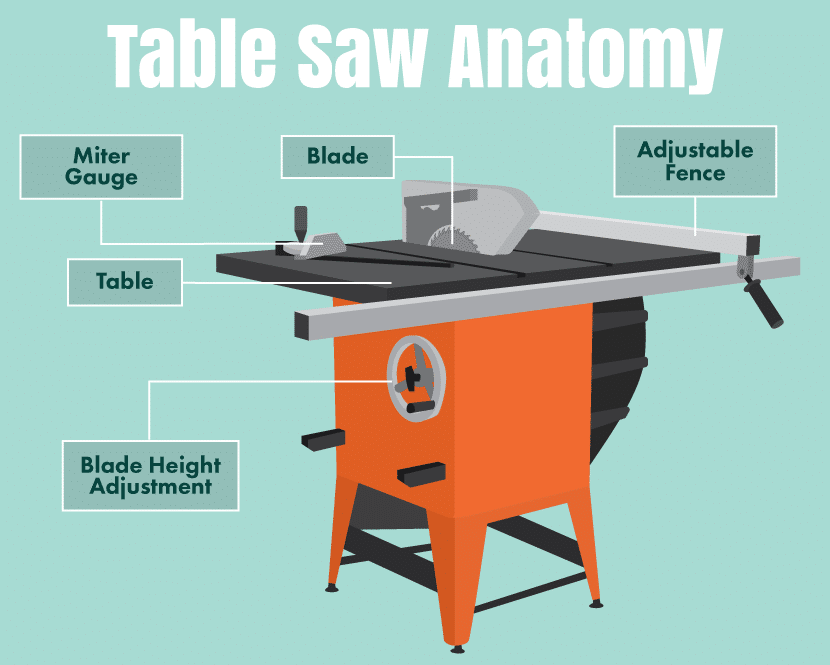

Apart from the blade, the following are the other components of a table saw. So, when you purchase a table saw, invest some time to know all the parts and their working.

- A working table worth 3 x 3 feet with extensions are available on most of the table saws. This table that’s generally made of cast iron, aluminium or steel, and rests on a metal stand or cabinet. Most of the table saws are stationary, but you can fold the cabinet/stand legs in some of the portable models.

- A rip fence that’s placed parallel to the blade. You can use the rip fence primarily for ripping.

- A mitre gauge that assists you in making crosscuts. It adjusts and allows you to change the angle of cutting material concerning the blade.

- Blade guards keep your fingers safe while using the table saw. The guards are very helpful, but they sometimes block the view of cutting material. Woodworking experts often remove them. If you are a beginner, we recommend you to leave the blade guards intact.

- Two wheels on the cabinet that re responsible for blade adjustment. One of them adjusts its height while the other one to adjust the angle of the saw blade. The latter is useful when you need bevel cuts.

- Depending upon the make and model, there might be other attachments or accessories like rollers, support extensions, clamps and vacuum attachment.

Whether you have an entry-level table saw or an industrial-grade heavy cutting machine, all of them has more or less the same of components that we mentioned above. Whatever you have, maintain it properly and use it with complete safety and care.

Table Saw Woodworking Safety Tips

Many weekend DIY woodworkers and professionals meet with unfortunate accidents, just because they don’t know how to operate a table saw. If you are not properly handling, the cutting material might bind and kickback. So, either it can come on your body or pull your fingers towards the blade. Minimize these risks and maintain your safety by following the given ways.

Wear Safety Goggles: Wood chips making contact with your face or eyes will need medical assistance. You need to consider the safety of your eyes before you start working on a table saw or any other power tool.

Keep Your Hands Away From The Blade. The best way is to use a push stick. Even if you have to reach near the blade, never try while it’s rotating.

Set Extension Table: Try to use the extension whenever you are cutting longboards. This will prevent binding as well as kickbacks and also eliminate the extra pressure that you need to apply on the cutting material.

Read The Instructions Manual: You should know how to operate the blade and other components of a table saw. The best resource is its instructions manual that gives you the safety previsions and steps you can follow to prevent kickbacks.

Power off the machine when you need to change or align its blade.

Choose The Right Blade

Almost all the table saws come with a blade, which works well for a wide range of tasks. However, if you want the best out of your table saw, you need to have a collection of blades. Teeth count is the primary factor that differentiates the blades.

Crosscut blades are available with teeth anywhere ranging between 60 to 80, while a rip cut blade has a maximum number of teeth between 10 to 40. A high number of teeth ensures smooth cuts.

Another factor that categorizes the table saw blades is their kerf, which means width. The amount of wood a blade can remove is known as its kerf. Most of the table saw blades come with full kerf, means the size is 1/8 inches. When you are cutting plywood, MDF or anything, you should use a blade with 3.2 inches. It will ensure smooth cuts and also waste less wood. Such a blade does not have carbide-tipped teeth and hence they will wear out early, but it’s all about precision here.

Make The Most Out of Your Table Saw

Crosscuts are easy for table saw, but so it is for mitre saws or compact circular saws. The primary job of a table saw is to rip cut the wooden materials. For that, you need to place the wooden board on the table, set the fence, switch on the table saw and move a cutting material towards the blade slowly and firmly. However, its more than what meets your eye, especially if you need accuracy and precision. If you use it according to the rules, then a table saw can make the best cross and bevelled cuts. Here are some tips that will help you to get you the best possible results.

- Check the fence distance from the blade using a ruler. Don’t rely on its fence gauge measurements until you have a commercial grade table saw. You should also check the blade’s height with a ruler.

- Keep the table saw clean and lubricate its parts after every couple of months. Also, cover it with plywood when you are leaving the workshop.

- Always use a sharp blade. Exhausted edges can produce burnt results and spoil your project.

- Don’t apply too much pressure on the cutting material while moving it towards the blade. Pushing fast might result in kickbacks.

- Cut the baseboard and plywood with their front side or face up. It will minimize the wastage.

- Use dado blades when you need to rabbets and grooves. Dado blades need the same installation methods as other blades, but they are available in a variety of shapes and sizes.