Last Updated on May 11, 2024 by Sharaj

Have you got a delicate project that involves detailed woodworking and intricate joinery? Look into your workshop arsenal and you will know that none of the tools can offer what you need.

However, a scroll saw can be helpful in situations wherein you have to make difficult cuts including curves, zig-zags etc. It’s also great for music instrument makers and DIY enthusiasts who enjoy making wooden toys, nameplates, and puzzles.

To complete such fragile projects, the scroll saw comes with a thin blade that might break easily. It’s the biggest disadvantage of using a scroll saw, but you can avoid blade breaking by setting the right tension and using it correctly. Check the Best Scroll Saws here.

Moreover, you should also know the limitations of a scroll saw. So that you don’t use the machine more than its ability. Using a scroll saw beyond its ability will provide you with below par results that you would not enjoy.

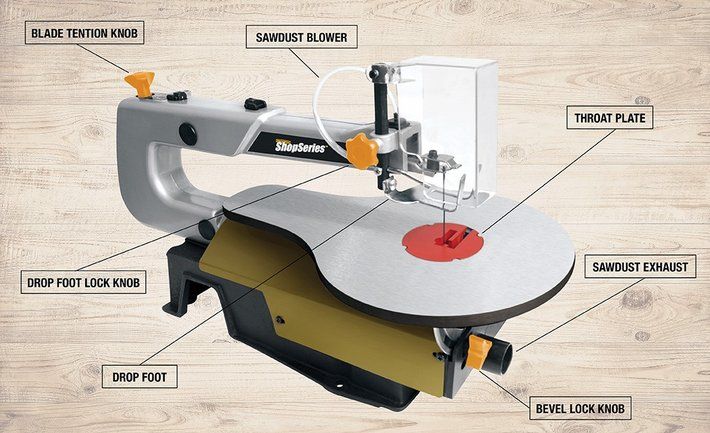

What Are The Parts of a Scroll Saw?

One glance at the scroll saw and you can notice its working table, but what you might not notice is the bevel lock knob. You can use this knob to set the table angle for bevel cutting.

When working on an angle, you also need to adjust the drop foot lock knob. It should rest on the workpiece parallel to the saw table. You need to loosen a Philips screw to bring down the drop foot and then tighten the screw.

As it’s clear from its name, you can use the blade tension knob to change the pressure on the edge. Do not tight the blade too much, otherwise it will easily break. Similarly, little tension might bend or break the blade.

Adding or reducing tension requires practice and understanding of scroll saw functions. You can know the scroll saw by reading its manual and start practising accordingly.

Finally, you will notice a speed adjustment knob that increases or decrease the blade’s speed. The speed depends upon the material you are cutting and the number of teeth on a blade.

As you see, there is no fence on a scroll saw because it’s not fit for rip cuts. You should use a table or band saw for ripping apart wooden materials.

Choosing The Right Scroll Saw Blade

A scroll saw blade exhausts quickly and you need to replace it for better results. Depending upon the material and its thickness, a scroll blade maintains its sharpness for two hours. Afterwards, you need to change or replace it according to the requirements.

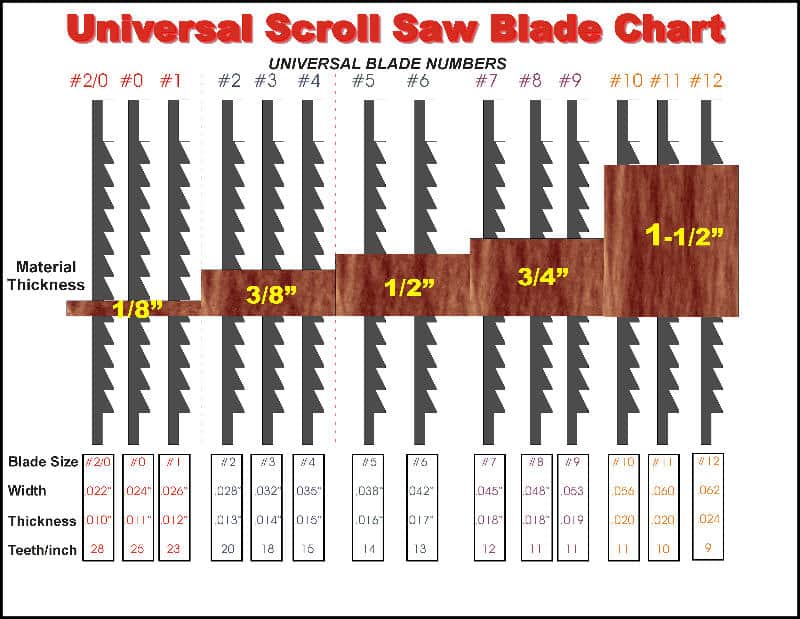

You should choose a narrow and fine teethed blade for up to ¼ inch thick materials. To cut thick wooden materials, you can use a blade with a higher number gauges. Such blades don’t give you a high level of accuracy, but due to their durability, you can use such blades to cut hard and thick materials.

The number of teeth and their style determines how fast a blade can cut. High teeth numbers mean fast cutting without much splintering and wood chipping. The situation changes with rough blades. Then comes the style of how teeth are present on the blade.

A standard scroll saw blade comes with teeth sitting at regular intervals and all of them point downward. Such blades are useful in most of the cutting situations.

There is another variety of blade sold as a skip tooth blade that has one tooth present at a separate position from others. Reverse skip tooth blade has teeth on the lower part pointing opposite to its other teeth. If you need splinter-free cuttings on both sides of the wood, choose a reverse skip tooth blade.

What Is The Use of Scroll Saw?

A scroll saw is useful in many such places where other cutting tools might not be effective at all. Most of the woodworkers, artisans and craftsman use the scroll saw when they need intricate cuts on plastic, wood or metal.

- Such a saw is useful for wood/ivory carvings, create wooden artwork, and similar tasks.

- Suitable for making puzzles and wooden toys.

- Carpenters use it to marquetry, wooden templates, lettered signs and inertia.

- Scroll saw is widely used by carpenters to make dovetails for cabinets and jewellery boxes.

- Manufacturers of musical instrument use scroll saw to make delicate wooden pieces of guitar, violin and similar items.

Tips & Tricks

All the power tools require practise and experience to reach perfection. A scroll saw is no exception. On top of that, you have to be extra careful while using a scroll saw because of its thin blade that can bend easily and ruin your work. So, set the blade right and position the cutting place properly to avoid unfortunate results.

Set the right tension: When you install a new blade, set it with both upper and lower armatures. Use the blade tension knob to adjust the pressure. Some of the woodworking experts’ states that a blade set with appropriate tension makes a middle C-note once you tap it. The point to make a blade tight enough to move and vibrate like a musical string. Do not overtighten the blade to get higher sounds then middle C, otherwise, it will break.

Hold the wooden piece with loose hands: You might it surprising, but you need to give some space to the workpiece so that it can vibrate a little. Pressing the material too hard against the blade might spoil the project. If you hold the lighter, the blade will pick at its easily without much resistance.

Avoid hogging: Pushing the material very fast towards the blade is known as hogging. It can easily bend or break the blade of a scroll saw. Hogging will also result in burnt cuts that will destroy your project. Move the blade slowly, so that the blade can take its time to cut.